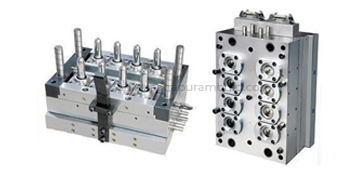

Pet Preform Mould Details

We are manufacturing all types of pet & pp preform injection mould.

Making a pet preform injection mould from 2 cavity up to 40 cavity preform mould. With all types of neck & size from 12 mm to 150 mm and different types of thread.

Feature of our pet preform mould

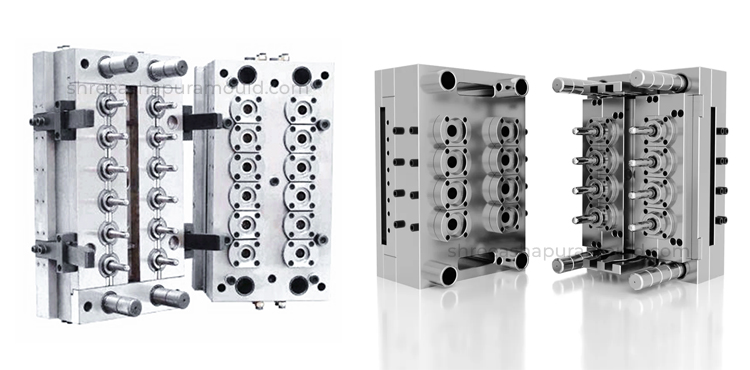

- With a proper mountation of hot plate in the back side of cavity plate.& and the proper gap between cavity plate and hot plate is maintain.

- Hot plate is such a mount that the proper flow of melt material is flowing properly in all cavities. So the wall thickness of preform is maintain with neglecting outness of preform.

- Extra thermocouple is provided for the hot plate.

- The proper weight set on the preform so the mould work smoothly.

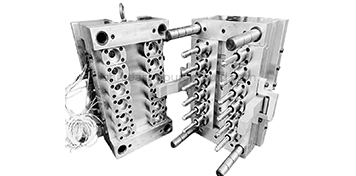

- The proper grooving is provide on the cavity insert so the cooling water flow around the face of cavity side.

- By giving proper inlet & outlet of cooling water, so the melt material is cooled down with in minimum cooling cycle time.

- For the cooling from punch the back plate is providing with proper inlet and outlet hole inside the plate.

- We providing a mould with high quality material so the life can be long of mould. And customers fully satisfied.

- Proper service is provide after selling the mould.

- C-clamp and bearing slider is mount on the side face of the mould for opening of slider plate on which the neck of the preform is mount and open the mould after one cycle.